Is There A Difference When Using Primer Colors

Thanks to the availability of Cyberspace information, anyone who has always sprayed a glaze of pigment can post their expertise online. This has led to a lot of bad or outdated data. People toss effectually terms like primer, sealer, two-part pigment, tri-coat, lacquer, single-stage, and it tin go confusing.

Let'south start past dispelling i of the most mutual misconceptions. Many clients ask their painters to apply lacquer. They recollect they will become a ameliorate paint chore by using lacquer. This is non true. Always run into a classic car with a paint surface covered in tiny cracks? That's because it was painted with lacquer. Unless you're painting a 100-point concours restoration, y'all shouldn't be using lacquer. Modern pigment is easier to apply, looks ameliorate, and is much more than durable that whatsoever lacquer paintjob.

How Paint Works

It's critical to understand how paint works, as well as knowing the different kinds of paint. New-engineering science paint works differently than quondam lacquer. Lacquer was made with very strong solvents. While this immune solvents to reach deep into the surface to class a strong chemical bond, it as well created a variety of serious problems like crazing and wrinkling. This meant when something when wrong, you had to remove all the pigment right downward to the metal.

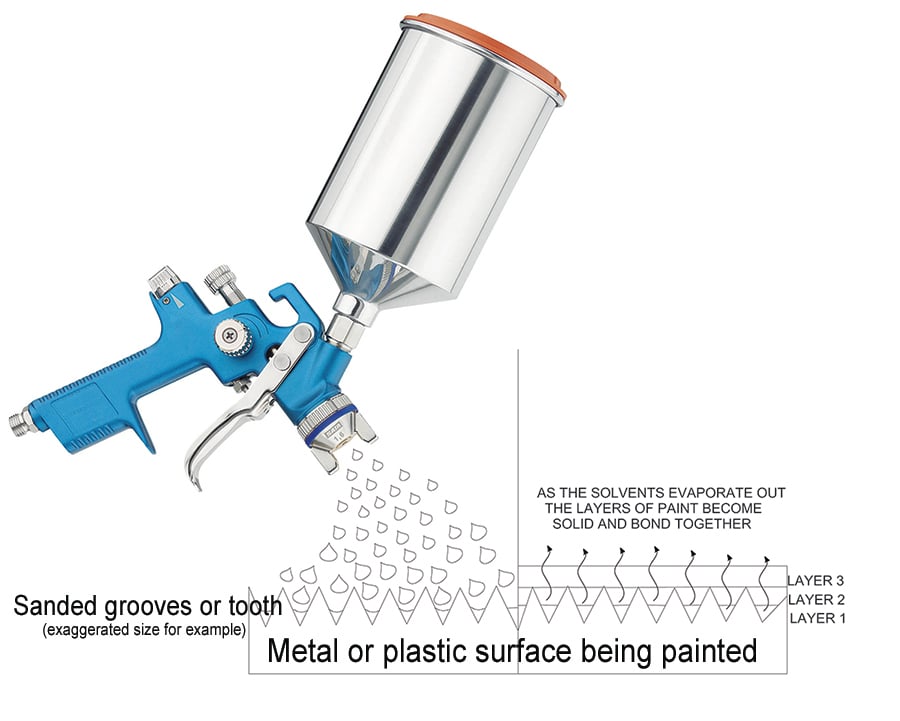

This is a very simplified drawing, but it'southward an easy-to-understand explanation of how modern-technology paint works. The paint is sprayed onto a sanded surface, and the sanded surface provides "teeth" to help the paint stick. The solvents in the paint, carry the pigments and resins to the surface, so equally they evaporate out, the layers bond together.

While urethane paints have a slight chemical bail, they actually demand "teeth" or sanded/scuffed surface to hold on to. This is why it is very important to understand the product you are using and what it needs. First, you lot need to know how to prepare the surface. What dust of paper practise you lot need to use? How long can the production sit down until information technology needs to be sanded earlier painting over it? This is called the "window." All of this information can be plant in the product's tech sheet.

The Paint Windows

There are two paint "windows" that affect the outcome: The recoat window between coats of pigment, and the recoat window before painting another round. So, what is a "round" and how is it different from a "glaze" of pigment? Say yous've done the bodywork and are ready for primer. You spray three coats of primer — waiting the recommended time between each coat before spraying the next glaze. These 3 coats are one circular.

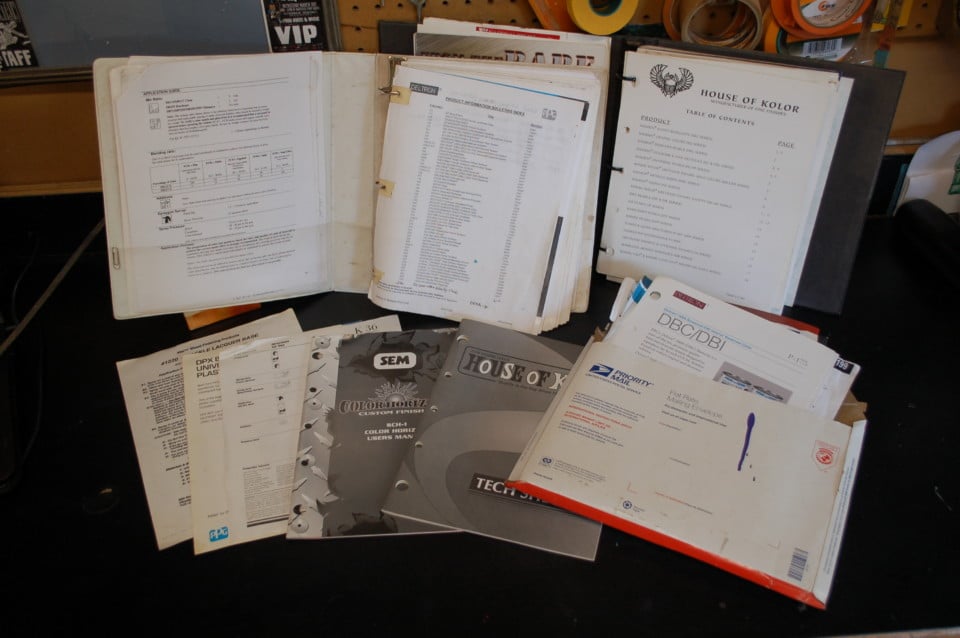

Hither's part of my library of tech sheets. A tech or P sheet explains everything you need to know about the product. What it can be sprayed over and how to set up the surface, the kind of spray gun that should be used, the air pressure needed, how the coat should be applied, recommended number of coats, time betwixt coats, recoat windows, and dry times. Yous'll besides acquire how it should exist mixed and what should be mixed with it. Yous should accept a tech or product sheet for every pigment production beingness used. Read through the canvas and follow what it says.

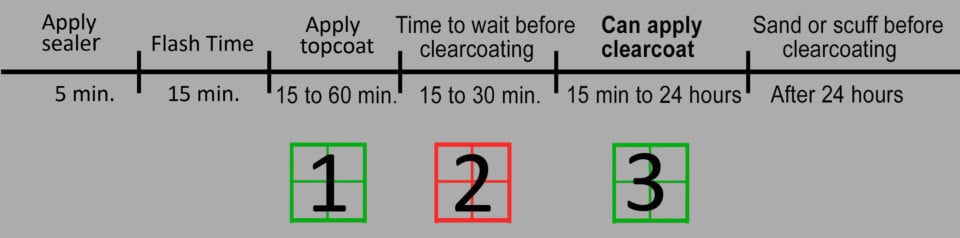

Then, the primer cures overnight. This is the window between rounds. Then, the primer is sanded and one coat of sealer is practical. The tech sheet for the sealer says it needs to dry for 30 minutes (some other recoat window), and and then one round of three coats of basecoat-color tin be sprayed. The basecoat dries for one hour (recoat window), and two coats of urethane clearcoat is sprayed.

The tech sheet volition tell y'all the recoat windows for the production. Many paint issues happen when the recoat window or window rules are not followed. Recollect, picture thickness can besides affect the recoat window. The thicker or heavier the coat, the longer it takes for the solvents to gas out.

Avoiding Delamination and Adhesion Problems

Follow the recoat rules on the tech sheet. If y'all go by the recommended time for recoat, accept the fourth dimension to sand or scuff that surface! Here's what volition happen if you cheat by but a small amount of time. If y'all're doing a ane-color paint job, sure the paint will look great —at offset. Then over time, yous'll detect the paint might chip hands, or bubbling might form under the surface, as the top coats begin to lift.

Only, if y'all're doing whatever kind of ii-tone or artwork, yous'll find the problems right away! Chances are, when you're removing any tape, the paint will come up with the record. Always paint past the rules of the tech sheet, no thing which product you're using.

Most paint products are designed to exist sprayed in certain conditions. For instance, it'south non a good idea to paint when it's very cold or very hot. Standard weather condition are temperature, humidity, and air menstruum under which an automotive paint product's dry time, cure time, pot life, and all full general functioning characteristics are determined. This information is plant on the products tech sail.

The xv-Degree Dominion

What happens when you try to pigment in colder or warmer temperatures than recommended in the tech sheet? This is where the 15-degree rule comes in. This rule pertains to two-part products, such as any pigment product with a catalyst or hardener. It explains how temperature tin affect a production'due south dry fourth dimension and pot life when painted in conditions that are hotter or colder than what is recommended in the tech sheet.

- For every 15-degree increase in temperature above standard conditions, a product'south dry time and pot-life may exist reduced by one-half.

- For every fifteen-degree decrease in temperature below standard conditions, a refinish production'south dry time and pot-life may be doubled.

Here's a timeline for the average paint job. For example, let'south say sealer has been sprayed and basecoat will exist applied next. This timeline is based on a seventy-degree shop. This is just an example, every bit all products will be different.

The term pot-life applies to 2K (two-part) products. The pot life is the corporeality of time a mixed 2K product can be used after the two parts — usually paint and hardener — have been mixed together.

What is VOC?

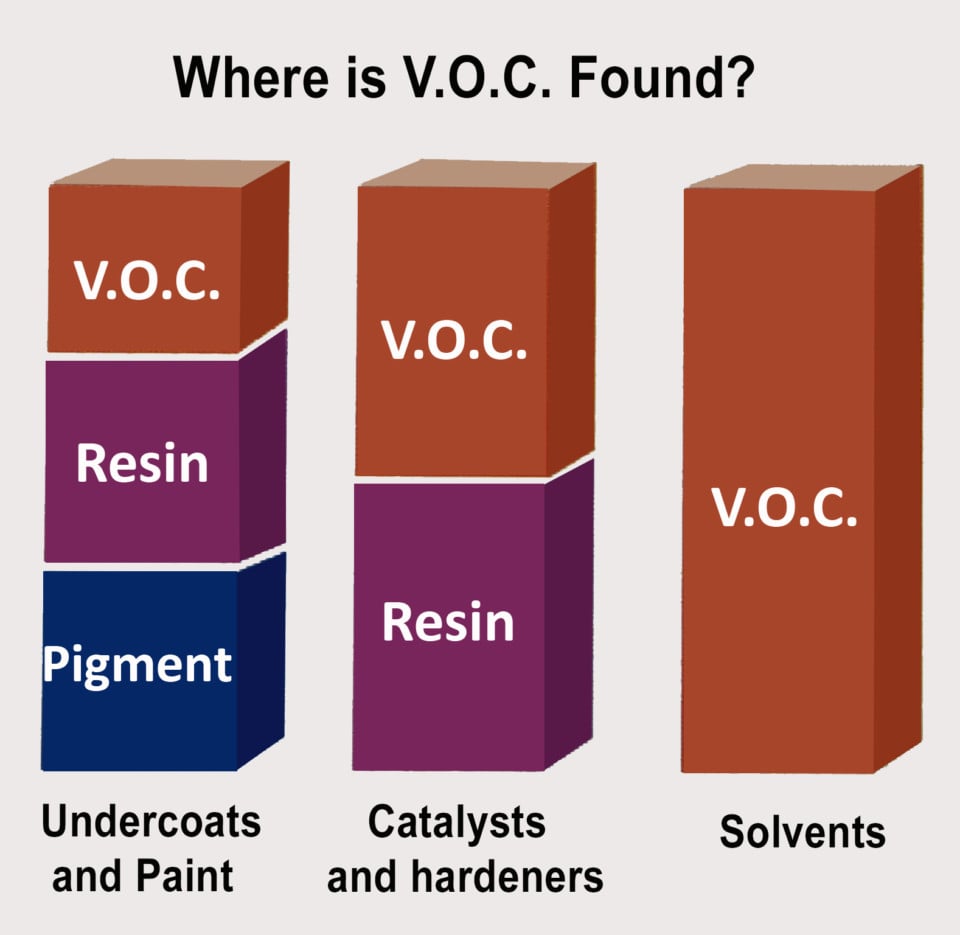

VOC is ane of those terms that gets tossed around and folks don't know exactly what it means. Volatile Organic Compound, or VOC, is a form of materials which include most evaporative-solvents used in machine-refinish products. VOC is found in nearly all refinish products. On Sept eleven, 1998, a new regulation was put into consequence which regulates the VOC level every bit practical to refinish products.

Automotive-refinish manufacturers tin can only sell undercoats, topcoats, and clearcoats which run into the police. Some states similar California, have enacted VOC regulations that are stricter than the national rule. Pigment companies have responded past creating h2o-based paint and solvent products that are VOC compliant. Subsequently in our Painting 101 Series, we'll cover understanding and using waterborne and water-based paints.

This graphic gives a basic await at each type of product in a refinish system and shows that each one contains VOCs. VOC is measured in pounds of VOC per gallon. VOC information for PPG products can be found on the product bulletin.

The Undercoats

A paintjob is only as good as its foundation. Don't employ a inexpensive primer under expensive top coats. And never believe the myth most using lacquer primers under acrylic enamel or urethane paint. Start your paint job right past picking a paint organisation and using information technology through the entire paintjob. Likewise many things can go wrong with pigment, then give yourself an reward by using products designed to work together.

Epoxy Primers

Think of epoxy primer every bit the foundation for your paint. These primers create a harder, more than chemically resistant coating. They're h2o resistant, have minimal shrinkage, excellent adhesion properties, and volition stick to bare metallic, primers, filler, and old paint. For example, you lot tin can spray epoxy primer onto a surface that's been sanded down to blank metal, repaired with trunk filler, and then feathered into the original paint. Empathize that epoxy primer volition non terminate or neutralize whatever rust that has started or is already nowadays. Make certain to remove and treat whatever corrosion earlier applying primer.

Refer to the tech sheet for the time the epoxy primer can be recoated before it needs to be sanded or scuffed. Missing that window is i of the biggest mistakes painters make. On the other end, pay close attending to the time the production must dry out before applying paint over it. With PPG's DPLV Epoxy Primer, depending on the goad used, the product must sit down for thirty to threescore minutes when one coat is sprayed. Merely, if two coats are sprayed the wait is 60 to 90 minutes. Yet, when applyingover body filler, the wait times are very dissimilar — one hour wait time for 1 coat. If spraying two coats, the product must dry overnight before applying over trunk filler. Wet sanding epoxy primer is usually the best way to prep it considering epoxy has a tendency to clog paper when sanded dry.

Polyester Primers

Polyester primer is a very thick two-part product and is used when there'due south a good deal of bodywork. Poly primer is neat for using over bare fiberglass and epoxy. It's a high-solids production and has minimal shrinkage. It sands easily and is perfect for getting those wavy panels straight. Remember of it as a sprayable body filler. Using this production can salvage hours of time. Get the panels direct with the poly primer, paint one round of urethane primer, sand it, and yous'll be set to go into sealer and color!

Evercoat's Super Build 4:i is a two-part polyester primer surfacer with keen filling capabilities to help get the surface apartment. It'southward likewise expert for holding down troublesome repairs on fiberglass and SMC plastics.

Subsequently spraying the poly primer, block-sand information technology with lxxx-grit to flatten the surface. Then practise most of the sanding with 180-grit, and finish with 220. This will provide the apartment surface you want. The courser grits work meliorate for getting the surface flat. They carve more finer, scraping away the high spots. The finer grits tend to remove less of the high spots, passing over the bumps.

Never wet-sand polyester primer! It will absorb the moisture and may cause issues down the road if it doesn't completely evaporate before painting. While polyester primers are corking for filling, they can be porous. Once you're finished sanding the polyester primer, employ a urethane primer or a sealer over information technology. Urethane primers are a meliorate surface for basecoats. The urethane primer is much denser and seals the polyester surface. Always check the product sheet to know what works best for the poly primer you're using.

Primer Surfacers

A quality urethane primer-surfacer will do a good job of leveling out the transition from plastic filler to metal, likewise as filling the sanding marks in the filler. But, don't effort to use primer-surfacer where plastic filler or polyester primer can exist used. Proceed to the recommended number of coats. That data — plus recommended air pressures and wait times — tin be plant in the product sheets. Each product is dissimilar, so make sure to read through the production sail before priming. Never leave a 2-part primer sitting in the spray gun. Virtually catalyzed primers start to harden in nearly an hour. Let each coat wink (dry dull) before applying the side by side.

K36 is a standard-build urethane primer. K38 is a high-build primer. K201 catalyst can be used with either one. They are both swell quality primers, sand beautifully, and are very like shooting fish in a barrel to use.

Urethane primers come in a standard and high-build variety. Urethane primers too take nifty filling qualities. Follow the instructions for mixing and flash times (dry times in betwixt coats). Primer surfacers shrink when flash times (normally five to 10 mins) are ignored. Do not utilise a hardener meant for one product with a different product.

If preparing the surface for sealer and topcoat application, apply 320-grit when block-sanding urethane primer-surfacer. It'due south rough enough to sand it speedily and flatten out any small imperfections. Then, wet-sand the surface with 400-grit. You tin can besides get-go by moisture sanding with 400-grit wrapped around a Durablock, or whatever block you experience will piece of work best for the surface. Spraying a light guide-coat on the surface prior to sanding shows the high and low areas, and helps proceed the body lines straight as you lot sand.

Sealers

Years ago, I never used sealer. Now, I don't even consider painting without beginning spraying sealer. Call up of sealer as an insurance policy. Sealer takes care of many problems. It creates a bond between properly sanded primer and the basecoat paint. Sealers help the paint to stick, and tin can reduce the risk of having the topcoat paint run. Sealer fills those calorie-free sand scratches and can diminish very slight imperfections. The sealer besides helps to "seal" the surface. The edges of the layers that were sanded-through tend to heal nether a glaze of sealer. If sealer was not used, they might show upwards through the topcoat.

Considering I use PPG'southward Deltron system, my favorite sealer is PPG'due south K36 primer as a wet-on-moisture sealer. It'southward mixed 4:two:two:1 with their DCU2021 Clearcoat, DT Reducer, and DCX61 Goad. I spray i moisture coat, expect about thirty minutes, so continue with the basecoats.

Sealers too assistance the basecoat to catamenia. But, since sealer isn't sanded, it will leave more texture if it's not sprayed apartment. If you get a grainy surface with the sealer, that surface will prove up in your basecoats. Look times can be critical with sealer. Wait too long, and sanding will exist needed in order to assure proper adhesion of the basecoat. Too short a wait time, and solvents might be trapped. Sealer adds to the cost of the paint materials, but the troubles it prevents makes it well worth information technology.

Colored sealers can likewise exist a big help. A white sealer under a low-cal basecoat, helps the topcoat to accept better coverage. Some sealers come in a range of colors, so check your paint brand for its sealer choices. PPG's Deltron 5-Seal DAS302 Sealers are offered in white, low-cal gray, and dark gray. There are some sealers than can be custom tinted to better match the topcoat color.

An Like shooting fish in a barrel Way To Avert Many Painting Problems

When using 2K products, the best fashion to avoid issues is to simply use the hardener or catalyst designed to become with that product. Information technology doesn't affair if your buddy tells you, "Sure utilise that, I do information technology all the time." You have a chance when using a hardener that goes with a unlike make of paint or filler. Chances are, something is going to go very wrong, and yous will never know the real crusade of the problem. If yous exercise non have the right hardener to get with the stuff you're using — stop, and look until you lot get the right hardener. Information technology'south never worth information technology to use questionable hardener!

Next time, we'll accept a close await at basecoats, and teach all y'all ever wanted to know about solid colors, metallics, candy, chip, and pearls. What is candy color and why does it need a base of operations? The best style to become that pearl color to glow. Why are black and white two of the hardest colors to properly spray? What is the trick to spraying a flake paintjob with minimal coats? And there will be some sugariness candy pigment photos to drool over. Understanding how paint works is the key to getting that perfect paintjob!

Is There A Difference When Using Primer Colors,

Source: https://www.chevyhardcore.com/tech-stories/paint-body/primer-sealer-choices/

Posted by: stevensprou1983.blogspot.com

0 Response to "Is There A Difference When Using Primer Colors"

Post a Comment